says

toooooo much choice!!

says

toooooo much choice!!

Well-Known Member

Hi,

Moving on from a previous thread ‘ Boosting H3 Neo National’ , the last post I made on that thread was to try boosting 2 sheets of rubber in slightly different ways and see what happens.

How much the sponge expands, and what difference is found in letting the doming subside before applying coats of booster and just applying booster at regular 24hr intervals regardless of the doming. Glue when highly domed etc.

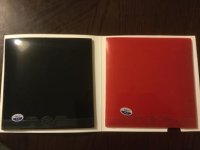

So the rubber I chose is Friendship RITC 729,

I bought the sheets from Tabletennis11, cost is €9.90 plus tax per sheet, which is a bargain!!!

Sheets felt tacky, and the sponge is fairly hard as a typical Chinese rubber should be!!

i don’t think this rubber is factory tuned??

Both sheets were measured before 1 thin coat glue (sealer) was applied.

Red sheet 164 x 167 mm,

This sheet will be allowed to have any doming flattened out, before the next coat of booster is applied. The sheet will also be left to allow the doming to subside before it is glued to the blade.

Black sheet 164 x 165 mm,

This sheet will have a coat of booster applied every 24 hrs regardless of any doming

As can been seen there is a slight curl to both rubbers straight out of the pack, possibly due to how it has been stored ? The curling is in the opposite way to what we would expect to see after boosting. After the protective film was removed the curling started to reduce straight away.

Both sheets flattened out completely after the thin coat of glue and 1st coat of Seamoon booster was applied.

So I’m going to apply 3 coats of booster in total. ( this could cause an issue with the black sheet if it domes heavily after the 1st couple of coats of booster, we’ll see how it goes.)

Hopefully the Black sheet will be on the blade after about 72 hrs ( 0 hr = coat 1, 24 hrs = coat 2, 48 hrs = coat 3, let dry, 72hrs glue on blade.

I have also got some DHS No15 glue, which is meant to be very strong, and will hopefully cope with the doming in conjunction with some weight compression !!!

The Red sheet could be a completely different kettle of fish!! This will depend on how the rubber domes up nd how long it takes the doming to go down!!!!

I’ll take a couple of photos in the morning and post, so we can see how the initial reaction to the booster is taking effect. Measurements will be taken every 24hrs, before the next coat of booster is applied.

I don’t have a Durometer to check the sponge hardness and see how this is effected by the boosting process.

cheers,

Moving on from a previous thread ‘ Boosting H3 Neo National’ , the last post I made on that thread was to try boosting 2 sheets of rubber in slightly different ways and see what happens.

How much the sponge expands, and what difference is found in letting the doming subside before applying coats of booster and just applying booster at regular 24hr intervals regardless of the doming. Glue when highly domed etc.

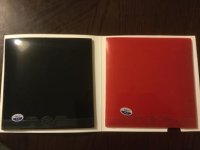

So the rubber I chose is Friendship RITC 729,

I bought the sheets from Tabletennis11, cost is €9.90 plus tax per sheet, which is a bargain!!!

Sheets felt tacky, and the sponge is fairly hard as a typical Chinese rubber should be!!

i don’t think this rubber is factory tuned??

Both sheets were measured before 1 thin coat glue (sealer) was applied.

Red sheet 164 x 167 mm,

This sheet will be allowed to have any doming flattened out, before the next coat of booster is applied. The sheet will also be left to allow the doming to subside before it is glued to the blade.

Black sheet 164 x 165 mm,

This sheet will have a coat of booster applied every 24 hrs regardless of any doming

As can been seen there is a slight curl to both rubbers straight out of the pack, possibly due to how it has been stored ? The curling is in the opposite way to what we would expect to see after boosting. After the protective film was removed the curling started to reduce straight away.

Both sheets flattened out completely after the thin coat of glue and 1st coat of Seamoon booster was applied.

So I’m going to apply 3 coats of booster in total. ( this could cause an issue with the black sheet if it domes heavily after the 1st couple of coats of booster, we’ll see how it goes.)

Hopefully the Black sheet will be on the blade after about 72 hrs ( 0 hr = coat 1, 24 hrs = coat 2, 48 hrs = coat 3, let dry, 72hrs glue on blade.

I have also got some DHS No15 glue, which is meant to be very strong, and will hopefully cope with the doming in conjunction with some weight compression !!!

The Red sheet could be a completely different kettle of fish!! This will depend on how the rubber domes up nd how long it takes the doming to go down!!!!

I’ll take a couple of photos in the morning and post, so we can see how the initial reaction to the booster is taking effect. Measurements will be taken every 24hrs, before the next coat of booster is applied.

I don’t have a Durometer to check the sponge hardness and see how this is effected by the boosting process.

cheers,