This user has no status.

This user has no status.

Well-Known Member

Yesterday I bumped into my former colleague who now is a partner in a small company which makes stuff from various plastics and while chatting got some strange idea. For some time I am struggling to find the racket case I like. (Don't be very judgmental, I know it's a little bit crazy, but I am somehow into luggage  . I have maybe some 8 backpacks (or maybe more..) ). So inspired and being envious (in a good sense) of the craftsman who make their own TT paddles I though it would be nice to try to make my perfect racket case.

. I have maybe some 8 backpacks (or maybe more..) ). So inspired and being envious (in a good sense) of the craftsman who make their own TT paddles I though it would be nice to try to make my perfect racket case.

I think the case should be:

-with rigid outer shell (like the "aluminum" ones) for maximum protection, cause I tend to overstuff my backpack with way too much stuff

-should look nice (that's subjective, but I am not a fan of a boxy "gun case" look of aluminum cases, so I imagine it should look somewhat similar to a hard shell plastic luggage which looks quite nice

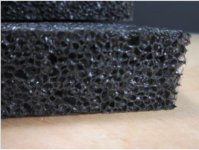

-should have foam for securing the racket and balls in place

-if possible it would be nice to fit 2 rackets in it while keeping the dimensions reasonable

So if we have time I will be meeting him next week to have coffee and to make some sketches.

I think it will be more expensive then the butterfly aluminum one, but I'll make it a Christmas present for myself.

Will post how my project is progressing

I think the case should be:

-with rigid outer shell (like the "aluminum" ones) for maximum protection, cause I tend to overstuff my backpack with way too much stuff

-should look nice (that's subjective, but I am not a fan of a boxy "gun case" look of aluminum cases, so I imagine it should look somewhat similar to a hard shell plastic luggage which looks quite nice

-should have foam for securing the racket and balls in place

-if possible it would be nice to fit 2 rackets in it while keeping the dimensions reasonable

So if we have time I will be meeting him next week to have coffee and to make some sketches.

I think it will be more expensive then the butterfly aluminum one, but I'll make it a Christmas present for myself.

Will post how my project is progressing