This user has no status.

This user has no status.

Member

Questions for Blade-Builders/Nate4s Build Thread

I know there are quite a few members here who build blades, so I was hoping to get some advice as I gear up to make a few for myself. I have already talked back and forth with Ross Leidy, who has been incredibly helpful in explaining parts of his process (as well as his thread over on OOAK), but I don't want to pester him too much and figured there are plenty of people with excellent blades and experience making blades on this forum. As I get further along in this process, the burning questions I have are:

1. I have used West-Systems G-flex epoxy for adhering knife scales to knife blades - it's waterproof, flexible, durable...and seems like it could have some interesting properties for gluing the veneer/core layers together. Has anyone ever used G-flex for building a table tennis blade? I have also picked up Titebond Veneer Cold Press and Titebond Polyurethane to try as well.

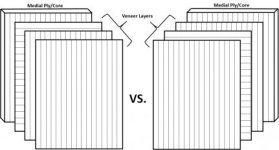

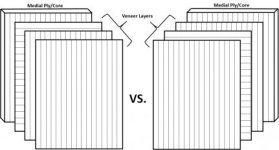

2. When making a 7-ply blade, would there be any significant difference between blades when just the grain orientation of the two outer plies differs? For example, in one blade, the grain orientation runs in the same direction (just for the outer two plies, as I understand the structural benefit of at least one cross-ply layer in the blade); in the other, the outer two ply grain orientations are crossed (see image).

3. In a follow up question to #2: Most blades seem to have a core with grains running vertically (from handle to apex of the blade) - are there positives or adverse effects of using a core-wood with grains running in the horizontal plane?

Unrelated to my questions, but just to preemptively address questions people might as: The veneer woods I have access to at this time are Black Limba, Koto, and Mahogany - unfortunately, just Balsa and Basswood for the core (I live on the Oregon coast, where Port Orford Cedar grows and is milled, so I'm working on acquiring suitable pieces to try as 1-ply and as cores).

Thanks in advance for your help!

I know there are quite a few members here who build blades, so I was hoping to get some advice as I gear up to make a few for myself. I have already talked back and forth with Ross Leidy, who has been incredibly helpful in explaining parts of his process (as well as his thread over on OOAK), but I don't want to pester him too much and figured there are plenty of people with excellent blades and experience making blades on this forum. As I get further along in this process, the burning questions I have are:

1. I have used West-Systems G-flex epoxy for adhering knife scales to knife blades - it's waterproof, flexible, durable...and seems like it could have some interesting properties for gluing the veneer/core layers together. Has anyone ever used G-flex for building a table tennis blade? I have also picked up Titebond Veneer Cold Press and Titebond Polyurethane to try as well.

2. When making a 7-ply blade, would there be any significant difference between blades when just the grain orientation of the two outer plies differs? For example, in one blade, the grain orientation runs in the same direction (just for the outer two plies, as I understand the structural benefit of at least one cross-ply layer in the blade); in the other, the outer two ply grain orientations are crossed (see image).

3. In a follow up question to #2: Most blades seem to have a core with grains running vertically (from handle to apex of the blade) - are there positives or adverse effects of using a core-wood with grains running in the horizontal plane?

Unrelated to my questions, but just to preemptively address questions people might as: The veneer woods I have access to at this time are Black Limba, Koto, and Mahogany - unfortunately, just Balsa and Basswood for the core (I live on the Oregon coast, where Port Orford Cedar grows and is milled, so I'm working on acquiring suitable pieces to try as 1-ply and as cores).

Thanks in advance for your help!

Last edited: