This user has no status.

This user has no status.

Member

Recently I've been experimenting with some different materials, different carbons, glass fibre and most recently textreme. I have to say that textreme is easier to use than a classic hybrid weave as the glue sits on top rather than between the different strands, as a result less glue is needed. It's also easier to cut, a high quality pair of scissors will do the trick. The downside is that it's more expensive than aramid carbon. As i believe this could be a world's first I thought I'd give it a thread of its own.

As for how they play? I don't know yet as I've only just completed these. One is for me and the other for Chris Fagyal who worked on the composition with me.

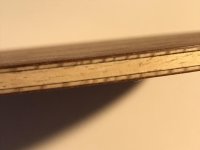

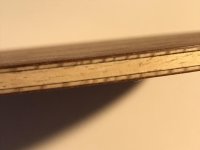

Blade 1 - Kiri - textreme - spruce - American redwood burl. 91g, 6.0mm. The handle wood is camphor burl and purple heart. This is quite a striking blade, lots of complex woods. This was made for Chris who likes exciting woods and always challenges my blade making skills. The handle woods were particularly difficult to shape.

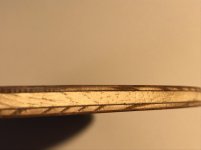

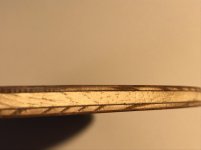

Blade 2 - Ayous - textreme - ayous - mahogany. 95g, 5.8mm. Handle wood is mahogany, rippled maple and walnut. The handle is one of my first conical designs. A very comfortable shape. There's a touch more weight in the handle (2 or 3g) due to the size of the handle which is 2.65mm high at the end and reduces to 2.45mm near the wings.

As for how they play? I don't know yet as I've only just completed these. One is for me and the other for Chris Fagyal who worked on the composition with me.

Blade 1 - Kiri - textreme - spruce - American redwood burl. 91g, 6.0mm. The handle wood is camphor burl and purple heart. This is quite a striking blade, lots of complex woods. This was made for Chris who likes exciting woods and always challenges my blade making skills. The handle woods were particularly difficult to shape.

Blade 2 - Ayous - textreme - ayous - mahogany. 95g, 5.8mm. Handle wood is mahogany, rippled maple and walnut. The handle is one of my first conical designs. A very comfortable shape. There's a touch more weight in the handle (2 or 3g) due to the size of the handle which is 2.65mm high at the end and reduces to 2.45mm near the wings.