This user has no status.

This user has no status.

Member

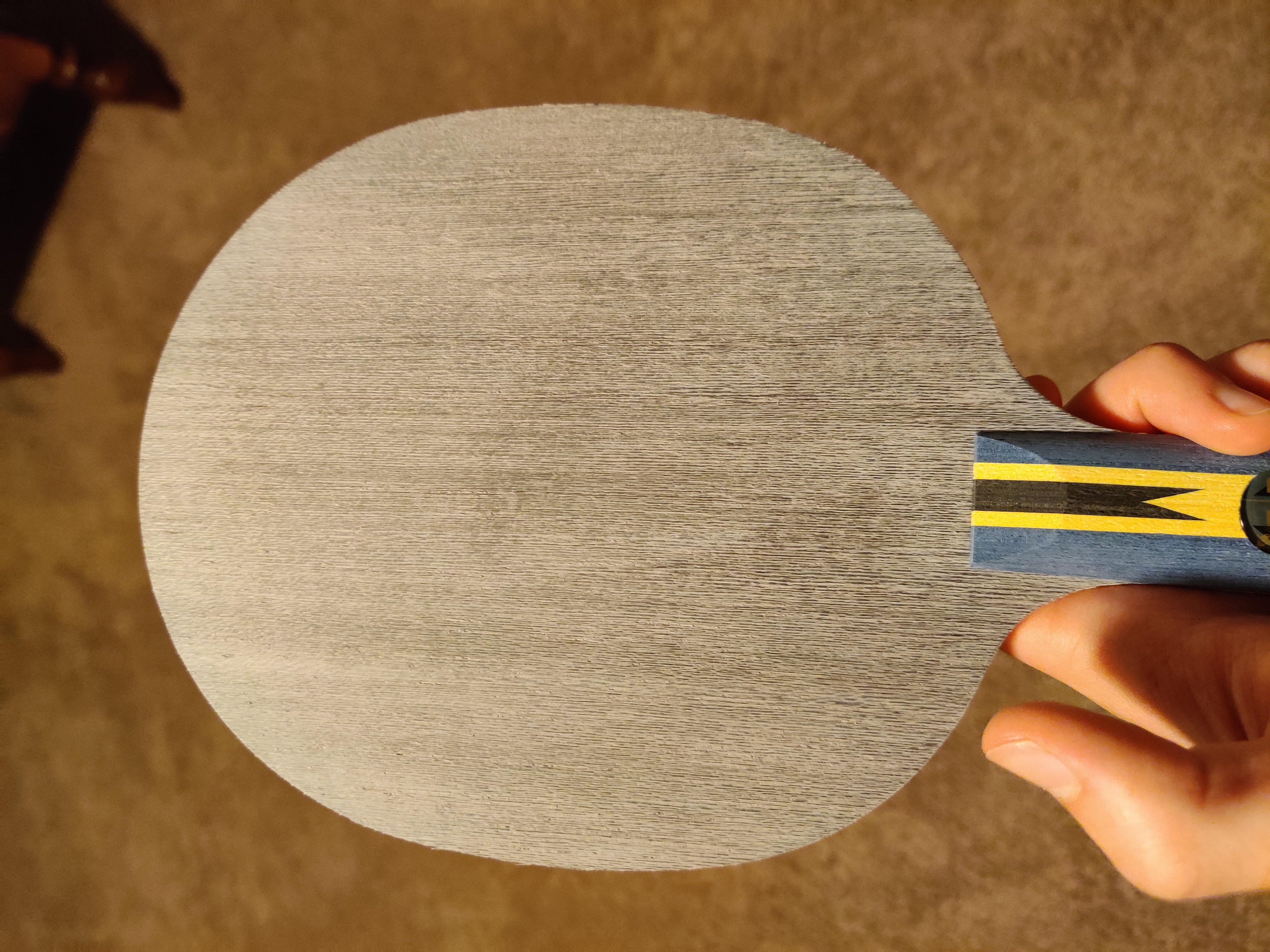

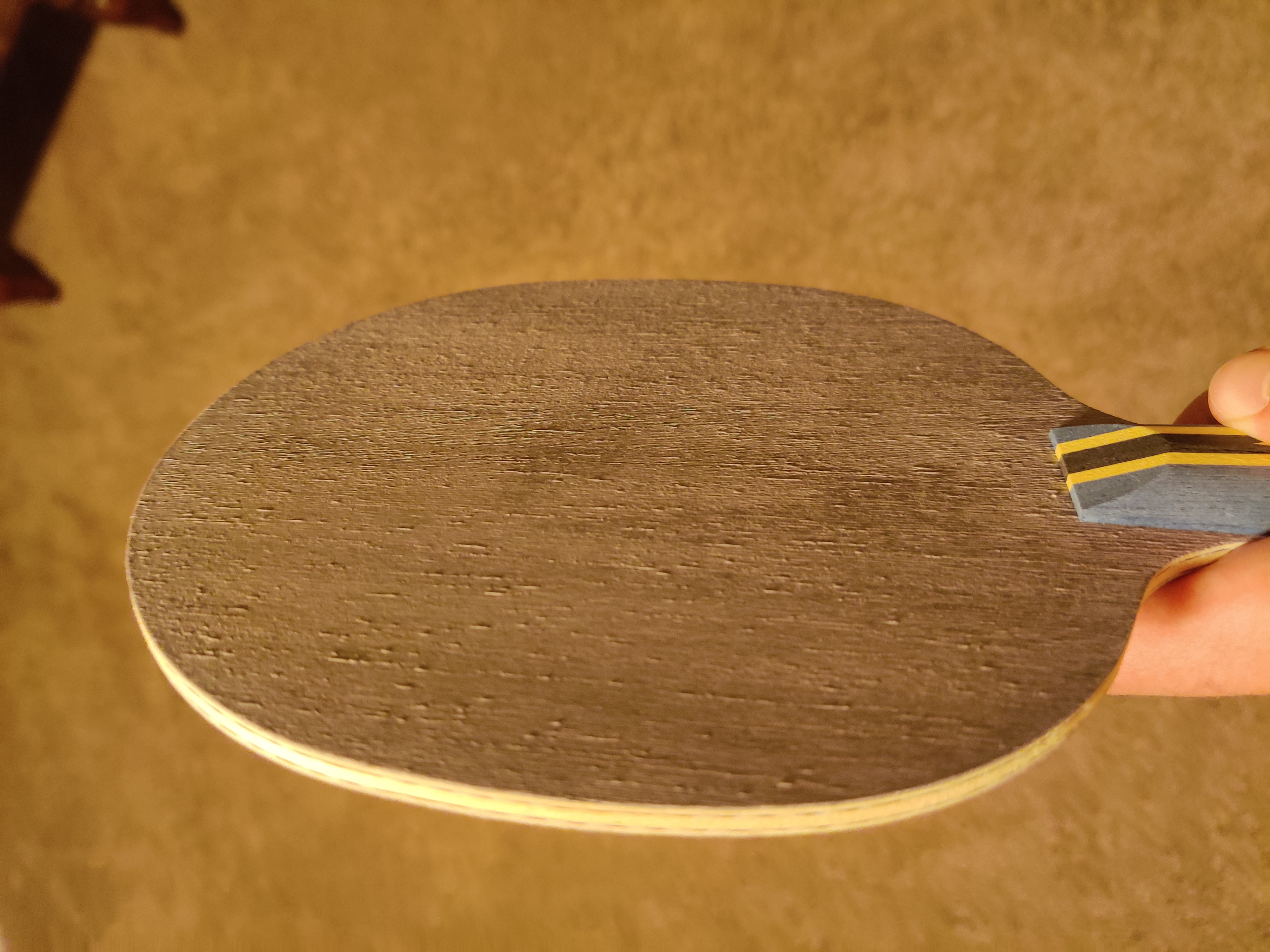

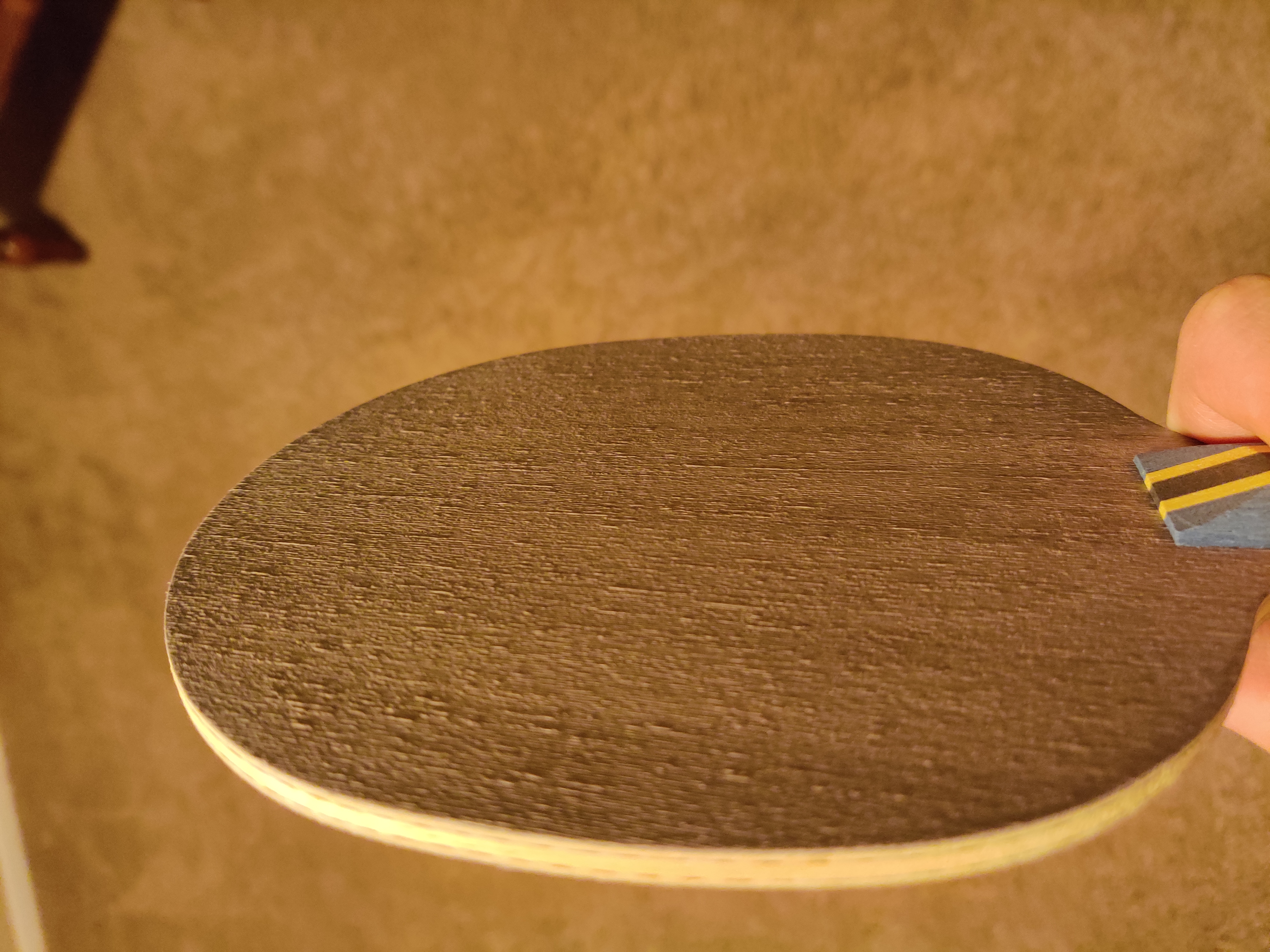

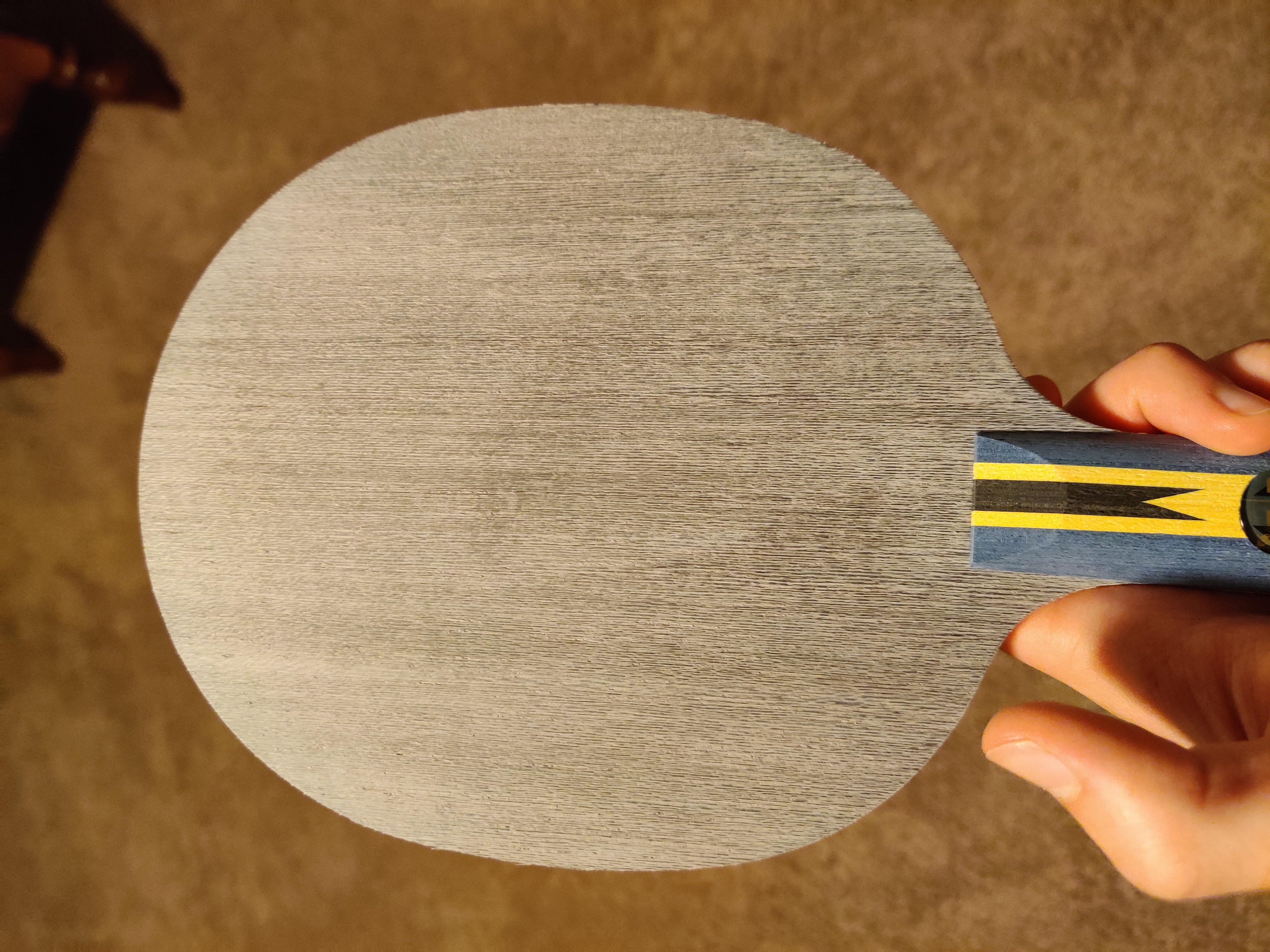

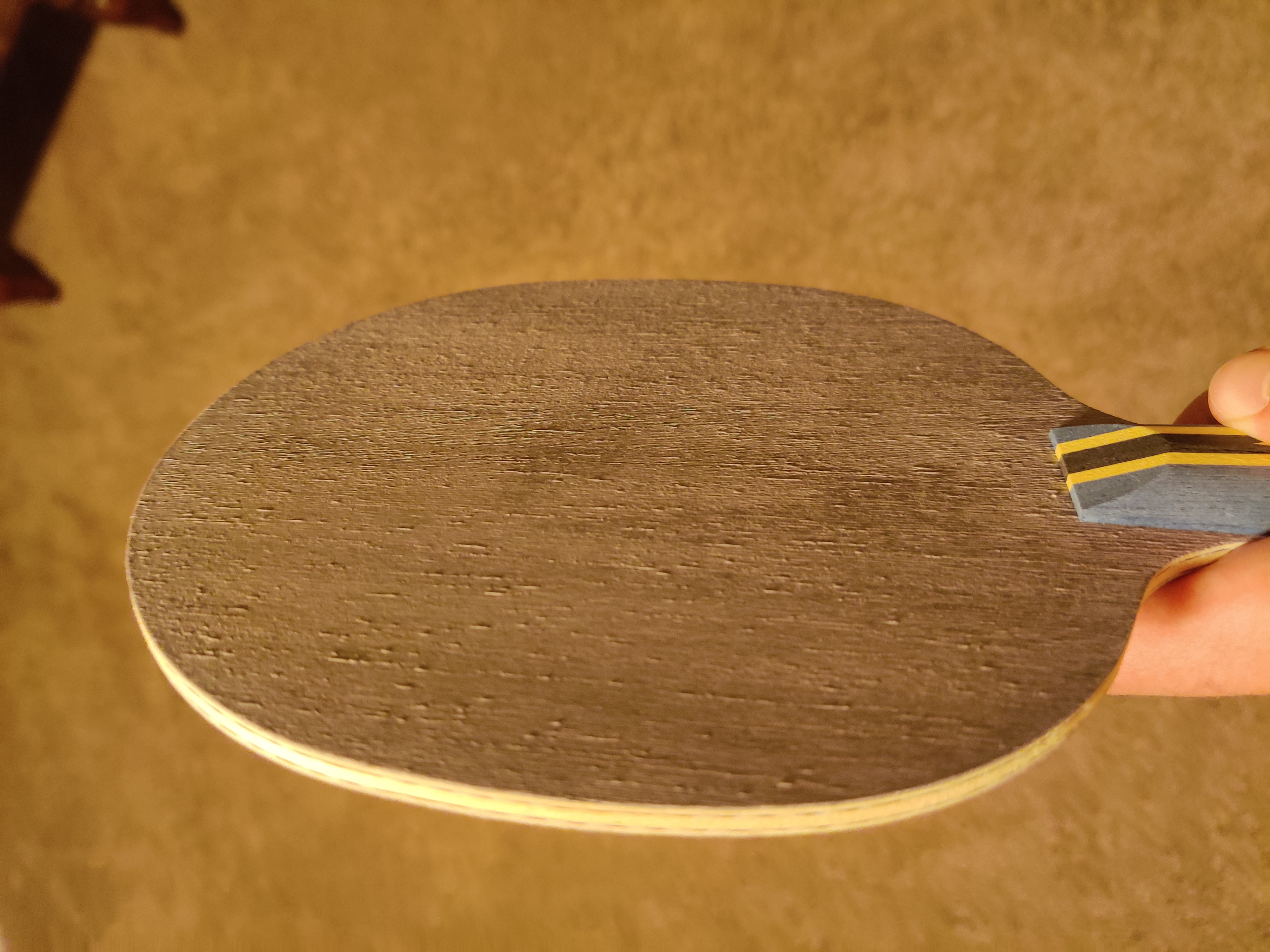

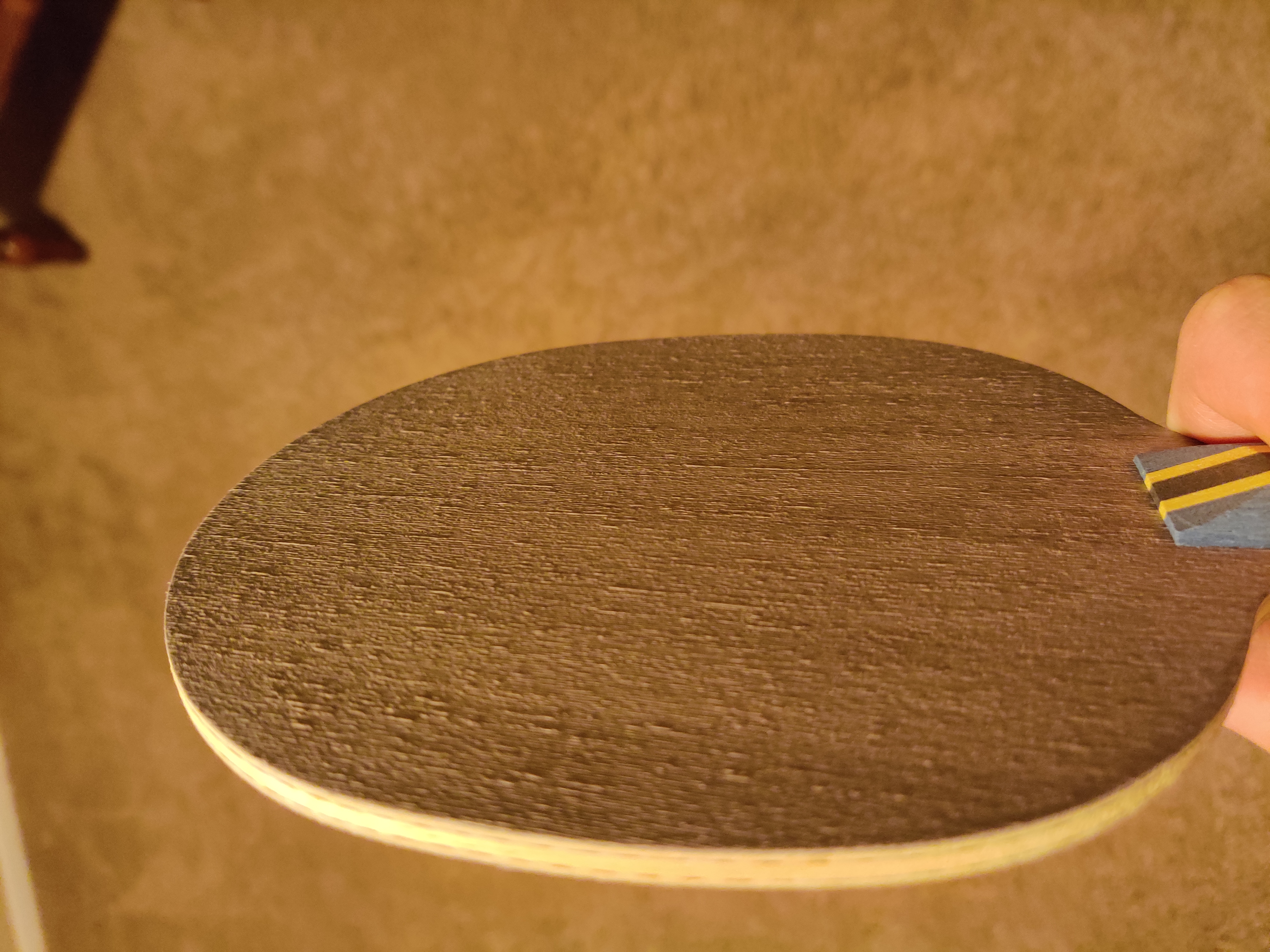

Hello! Today, I've received my new DHS Hurricane 301T blade after waiting about a month. I sealed the blade with JOOLA's blade sealing varnish. After waiting a couple of hours to let it dry, I come back to notice that the faces of the blades became coarse. Is this supposed to happen? Is it alright if I glue my rubbers on? I don't want to have the blade splinter when I change out the rubbers, because I want to use this blade for a good while. If anyone has any advice on what to do, let me know!

Images/Video

https://www.youtube.com/shorts/fGsBUM8ly3M

Images/Video

https://www.youtube.com/shorts/fGsBUM8ly3M

Last edited: