This user has no status.

This user has no status.

Member

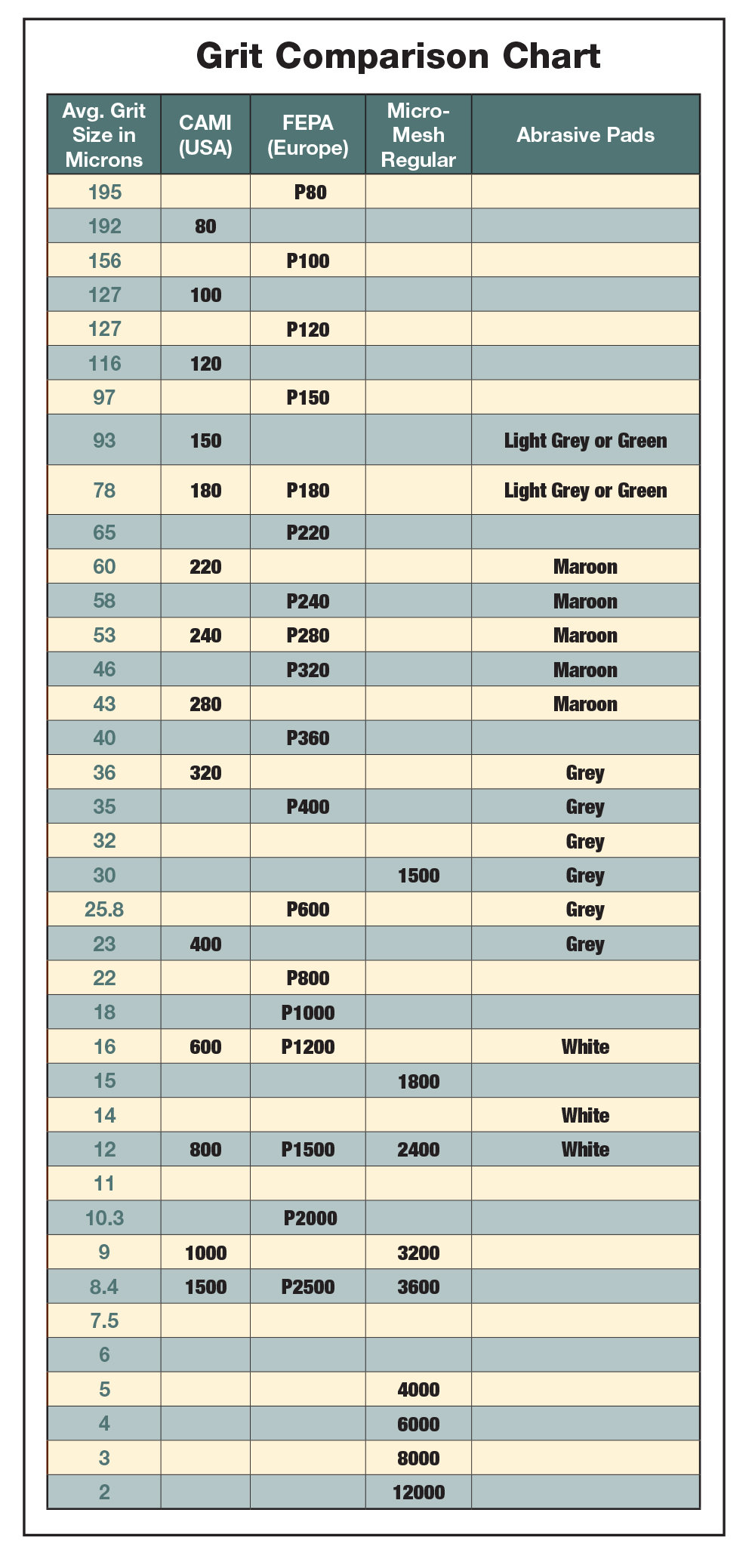

I use Joola Varnish as well, and I notice the grains lifting up on my blades too, though not as bad. I usually sand it down a bit with 1500 grit sandpaper wrapped on something that's flat. But now I think I'll follow @hipnotic's advice and use 180+240 in the future.

When you used the Joola Varnish, did you spread it over the entire blade face to become wet (Like how this guy did in his thumbnail)? Or did you just dip the brush in once or twice and just spread it over the blade face?