This user has no status.

This user has no status.

Well-Known Member

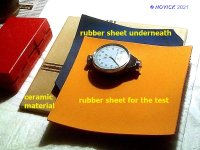

This is interesting. The guy shows his hardness measurements. He shows D09c is 55d which is what we all expected. He shows G09c comes at 54d, which is surprising to me.

But what confuses me the most is that he shows H3 40 to measure at 58d. Based on most of the conversion charts that I have seen, I would have expected H3 40d to measure around 54d ESN.

So would H3 41 be like 60d ESN? I have a 41d H3 right now, but it doesn't seem insanely hard to me.