This user has no status.

This user has no status.

Member

Hey! Great to see you here.

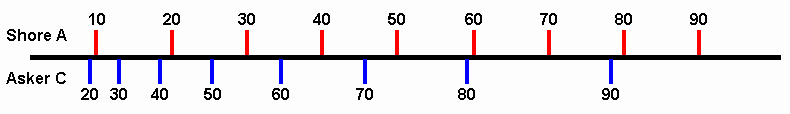

According to the conversion charts, H3 40 should be 54d on ESN scale. But when you measured it, it showed 58d after boosting. Why would it be so much harder than the conversion chart says?

I will repeat the measurement on a different rubber, maybe something was wrong with this one. I am waiting for the personal rubber from Chen Meng to arrive, also 40d. And some more Loki and Victas rubbers, so I will measure them as well. I will let you know how much I measure on the Chen Meng rubber before any gluing or booster.