Apparently there's nothing really special about these blades, but this was one of the most difficult challenges I had so far, but also one of the most fulfilling given the successful outcome.

This is what the customer wrote about his experience:

"I've been using a custom Kevlar blade that was made back in the 90s that I like better than anything I've ever used. Aside from the great feeling and playability of it, what's really special about it is the handle. It was made using the ORIGINAL prototype of the ASTI Carboflex Lillieroos model that was introduced in the 90s and has long ceased production.

Being a one-of-a-kind blade, I figured I'd better see if I could get a decent replica made because if I were to end up breaking it or losing it, I'd have no chance of getting a decent replacement. My initial search led me to a custom blade maker here in the US and I shipped my blade to him to try to replicate. Long story short, it just didn't work out and I resumed my quest to find someone else who was willing to try. Here on this forum I discovered SDC Blades.

Now Sergio (of SDC) is in Portugal so shipping my blade to him was not a practical option. So relying solely on photographs from various angles and specific measurements he asked me for, he felt that he had everything he needed to proceed. We communicated via email frequently throughout this process and I quickly became confident that he was up to the task. Since I was not certain of the particular woods that were used to make mine (aside from the single ply of Kevlar), I asked him to make two different variations in hopes that at least one of them would end up with similar playing characteristics to mine.

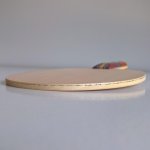

Upon completion he sent me photos of the finished products and it looked like the handles were very, very close to that of mine. But how would they feel and play? I'd have to wait about nine more days to get them in my hands to see for myself.

When I received them, I extremely impressed with the end result. The craftsmanship and attention to detail was just exceptional. And then I put some rubber on each of them to put the to the test and was pleasantly surprised to find that both of them played so similarly to my own that I know I could use them interchangeably without any concerns. And on top of this, his price was extremely reasonable. Including currency conversion and shipping fees, the final bill was just a bit over $200. I couldn't be happier with the end result.

So if you're considering having a custom blade built, SDC should be on your short list. Sergio is a master at his craft and goes the extra mile to make sure his customers get exactly what they want."

Just to add a bit of information to his post, when he came to me he had almost no information on the blade composition other than the obvious central Kevlar layer. So I had to rely on photos to guess the composition. To make matters worse, the blade is over 20 years old and fairly used so the wood layers were not clearly visible. Apparently it looked like a 4+1 composition, with two thick Ayous medial layers and maple top, but something was off because the layers were all aligned vertically. This means that the only layer with significant lateral stiffness was the Kevlar, but being placed in the center this contribution was really small. So I suggested that we might try incorporating two horizontal plies by subdividing the thick medial layers in the second blade, which would help stabilizing the blade and give it a bigger sweetspot. After building the blades, to my expectation, the first one warped. This confirmed my initial suspicion, and with a closer inspection of some new photos I discovered what seemed to be a really thin fiberglass layer under the top ply. I wasn't sure that this would be enough to give the blade sufficient lateral stability but tried it anyway. It turns out it was, making it a 4+3 composition, which is even more uncommon. So these were the two blades I sent him:

Blade 1: Maple / Glass-fiber / Ayous / Kevlar / Ayous / Glass-fiber / Maple

Blade 2: Maple / Ayous / Ayous / Kevlar / Ayous / Ayous / Maple

Since the beginning, the customer's biggest preoccupation was getting the handle right. In the end I understood why, this asymmetric semi-anatomic handle is one of the most comfortable I tried so far.