says

Spin and more spin.

says

Spin and more spin.

Well-Known Member

Super Moderator

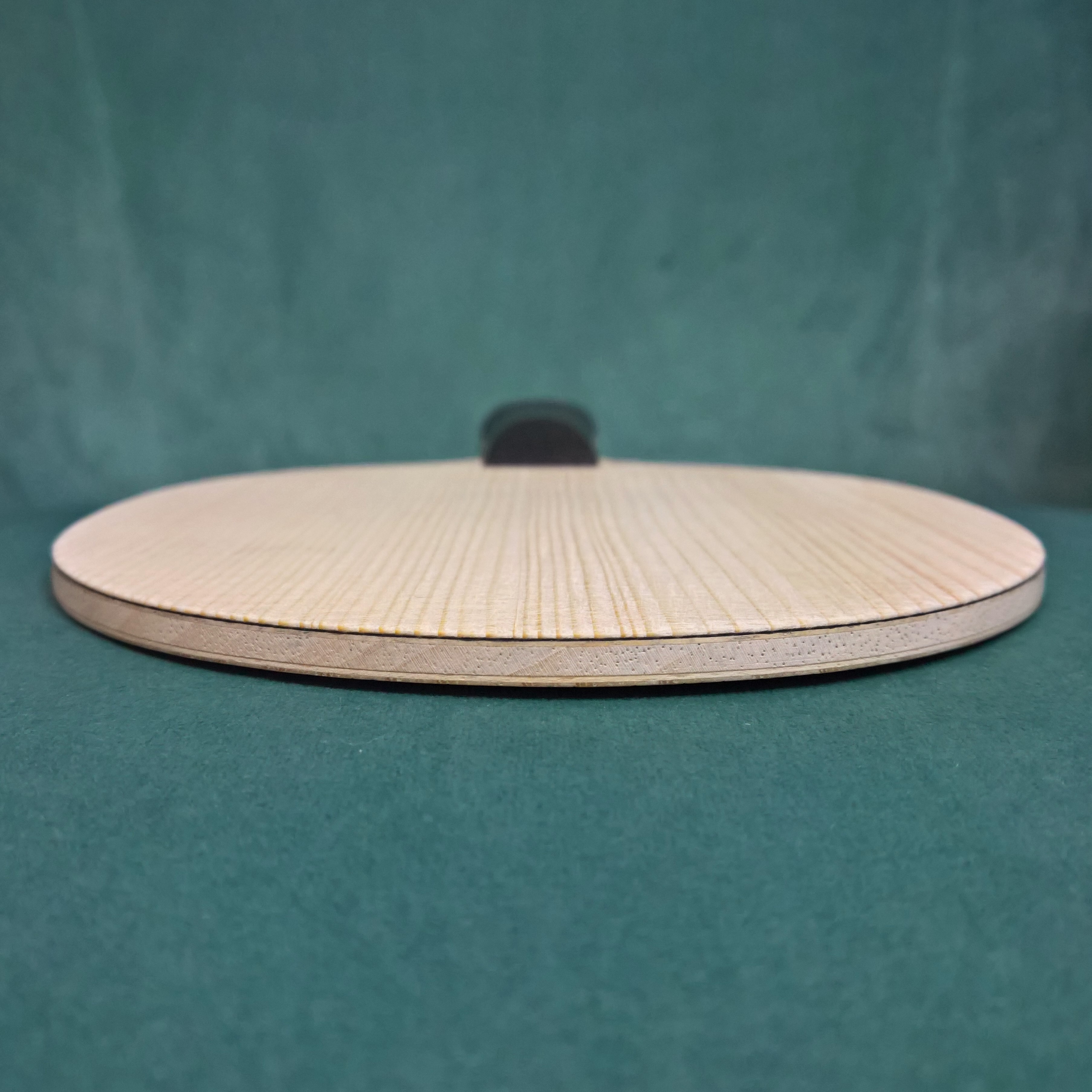

I think you misunderstood me. Of course the top ply is quarter sawn because it has the "fish scale" pattern that indicates it has been quarter sawn. Different wood grains show different patterns when quarter sawn.Yes, Ako has a very similar grain structure to Koto, but it's softer. Quarter sawing exposes the medullary rays and produces that effect, what we like to call fish scale.

Is the Olive Wood on the handle also Quarter Sawn? Or is there some other reason it has such a cool grain effect?