This user has no status.

Well-Known Member

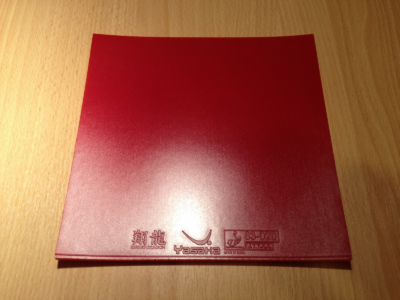

Xiom Vega Intro vs Yinhe Moon

Xiom Vega Intro has somewhat of a durability problem for me. I'm using it as the BH on a YSE and have maybe 10 hours of play time and about 500 hits with it on a ball spinner trainer. If I hit the ball spinner trainer a bit wrong it catches a piece of plastic wrong and tears the topsheet easily. I now have about 4 tears in the topsheet and can only imagine what contact with the table would do.

In comparison, I've also used Yinhe Moon to train my BH on the ball spinner as well as Yinhe Mercury 2 on FH. With the topsheet of these rubbers, there is no tearing or surface damage on my mis-hits.

To me as a beginner, Yinhe Moon feels pretty close to Xiom Vega Intro in terms of speed. I can't comment on spin since my BH is mostly flat drives and blocks (though I can lift backspin with it in training). I know most people would not consider it an beginner tensor (Yinhe markets its tech MaxTense) but Yinhe Moon is what I'm sticking with as my intro 'tensor' rubber for a bit. I ordered the Yinhe Moon 12 Blue and will test that out too (was curious because there were no reviews and it's blue!)

Xiom Vega Intro has somewhat of a durability problem for me. I'm using it as the BH on a YSE and have maybe 10 hours of play time and about 500 hits with it on a ball spinner trainer. If I hit the ball spinner trainer a bit wrong it catches a piece of plastic wrong and tears the topsheet easily. I now have about 4 tears in the topsheet and can only imagine what contact with the table would do.

In comparison, I've also used Yinhe Moon to train my BH on the ball spinner as well as Yinhe Mercury 2 on FH. With the topsheet of these rubbers, there is no tearing or surface damage on my mis-hits.

To me as a beginner, Yinhe Moon feels pretty close to Xiom Vega Intro in terms of speed. I can't comment on spin since my BH is mostly flat drives and blocks (though I can lift backspin with it in training). I know most people would not consider it an beginner tensor (Yinhe markets its tech MaxTense) but Yinhe Moon is what I'm sticking with as my intro 'tensor' rubber for a bit. I ordered the Yinhe Moon 12 Blue and will test that out too (was curious because there were no reviews and it's blue!)