This user has no status.

Member

I've been interested in finding out more about the Nittaku versions of the DHS hurricane 3 rubbers for a while, and have found little conclusive information about them. As far as I can tell, there are 4 versions.1) Nittaku Hurricane 3 pro

2) Nittaku Hurricane 3 neo

3) Nittaku Hurricane 3 with red packaging

4) Nittaku Hurricane 3 with violet packaging

I've never seen 3 or 4, but the descriptions I've seen of them all seem to indicate that they have a japanese sponge. I emailed tabletennis11 to ask about all 4 versions, and how the differed from the normal, commercial, DHS versions. I've read that tt11 are the official sellers of DHS products in Europe so I thought they might have some accurate information. The following was their exact response (my comments in red):

1) NITTAKU Hurricane Pro 3 has japanese sponge. Topsheet is the same (I presume they meant the same as normal hurricane 3).

2) NITTAKU Hurricane Neo 3 (8701) has japanese sponge. Topsheet is the same (Again, i presume the same as normal hurricane 3 neo).

3&4) Absolutely similar characteristics (as each other). Violet was produced for Japanese market.

As will shortly become clear, their information about Hurricane 3 pro is not correct. I can't yet comment on the rest though.

I have bought a sheet of nittaku hurricane 3 pro and a sheet of Nittaku hurricane 3 neo. Pro is listed on their website as available in 1.6, 1.8, and 2.0, while they only sell neo in 2.0. I ordered both in 2.0; pro in red and neo in black. They both turned out to be 2.1, according to the markings on the sponges.

The Hurricane 3 pro marking on the sponge on mine look exactly like this

While the Neo looks like this (sorry, I didn't have the foresight to take pictures before boosting, and couldn't find a good picture online)

Clearly, the hurricane 3 pro sponge is a normal DHS #20 sponge in 39 degrees, not a Japanese sponge. The +/- 2 degrees was unexpected. From what I'd read of these rubbers, they were supposed to have high quality control standards. Provincial hurricane 3 comes without any error in the hardness rating on the back of the sponge (from what I've seen of pictures online. I've never used provincial, only commercial H3 and H3 neo, both unboosted). Of course, just because it says +/2 doesn't necessarily mean that it might actually be between 37 and 41 degrees (which is a big margin for error on the DHS scale), but I'd be surprised if they went through the trouble of high quality control and then put that on the sponge. Does anyone know if commercial Hurricane 3 has error margins written on the sponge? I don't want to take my sheet off the blade and check. The Neo sponge I can't really say much about. Perhaps someone else has more information. Overall, the whole rubber on the pro is much harder than the neo. The neo is quite flexible.

One of the main things that got me interested in these rubbers was a post I read about someone (I think on this forum, I don't remember) who said they could read chinese and were reading through a chinese forum where they took apart the top sheets of a few versions of Hurricane 3, and found that Hurricane 3 national had a different pip size and structure to other versions such as commercial and provincial, and that Hurricane 3 pro was the only other version that had the same unique pips, likely meaning they were the same or similar topsheets. I don't know if Nittaku hurricane 3 neo was included in their testing. From looking at the top sheet, the pips are very clearly visible, somewhat like the sheets of Hurricane 3 national I've seen on the forums, though I've only seen pictures of black and mine is red. Once I've glued my sheets on I'll take some pictures.

Now onto the fun stuff. I decided to take my first steps into boosting by experimenting with these rubbers. I am using Falco tempo long booster. The Neo came with the usual vacuum packing and a layer of glue on the bottom. I didn't remove the layer of glue and applied the booster on top of it. The pro arrived just like any other sheet of hurricane 3, no vacuum packing, no glue. I'd read that I should add some glue first before adding the booster, so I put a thin sheet of Donic vario glue on the pro. I then put the booster over the top. I suspect I didn't wait long enough for the glue to dry, because I created rather a big mess, with bumps and lumps and unevenness. Anyway, I put a medium thick layer of the booster on both sheets and waited for around 11 hours.

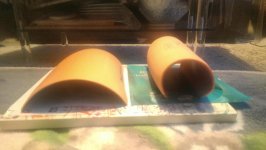

This was the result:

The neo was actually a little more domed than the picture shows. I flattened it a little by hand, rather stupidly, when I took the picture.

At this point, both sponges were still quite wet, and clearly not more than half of the booster had soaked in. Since I had created a big mess on the pro, I decided to wipe everything off the sponge with my fingers and reapply. This picture was actually just after I wiped off the glue and remains of the initial booster layer, and a couple of minutes after I applied the second booster layer, slightly thinner than the previous layer, this time onto the dry sponge. I added an extra layer, very very thin, to the neo.

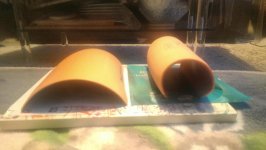

4 hours after that, this was the result:

Both are now more domed. Interestingly, whereas the pro had not dried after 11 hours when I put the booster over a layer of glue, now that I had wiped the glue off and put the booster straight onto the sponge, it was virtually completely dry in less than 4 hours. At this point I put a third layer of booster onto the pro, and left the neo untouched.

7 hours after the previous picture, 22 hours since initial layer was applied:

Actually the pro is domed more than this shows. If left alone it folds back on itself and a bit of the sponge rests against the topsheet. Since I didn't want to potentially get booster onto the topsheet, I aligned the two ends of the sponge so this wouldn't happen. I strongly suspect the pro 3 would have got to this point a few hours sooner if I had just put the first layer onto the sponge directly and not messed around with adding a layer of glue first. The neo is still quite wet and clearly a lot of the booster hasn't yet soaked in. Perhaps I should have removed the layer of glue it came with.

I won't be adding any more booster to the pro 3, and will wait as long as I see fit before gluing it on. I will see how the neo behaves over the coming hours and days before deciding whether to add any more booster. The neo is still much more supple than the pro, probably due to the topsheets. When they're done, they're both going on either side of a DHS pg7 (the big face means I can then put it onto my main blade, the Carbonado 145, if I really like either one). I'll then put up a review of how they play, compared to unboosted commercial Hurricane 3 neo, and hurricane 3-50 (hurricane 3 with tinarc sponge, from what I gather, so essentially hurricane 3 + softer sponge), which are both currently on the PG7.

Apologies for the long post. My aim is to get some more information about these rubbers out there. If anyone has any more information, questions, requests, or recommendations, please add them to this thread.

I'll keep this updated in the coming days with regards to how the boosting is going and how they eventually play.

2) Nittaku Hurricane 3 neo

3) Nittaku Hurricane 3 with red packaging

4) Nittaku Hurricane 3 with violet packaging

I've never seen 3 or 4, but the descriptions I've seen of them all seem to indicate that they have a japanese sponge. I emailed tabletennis11 to ask about all 4 versions, and how the differed from the normal, commercial, DHS versions. I've read that tt11 are the official sellers of DHS products in Europe so I thought they might have some accurate information. The following was their exact response (my comments in red):

1) NITTAKU Hurricane Pro 3 has japanese sponge. Topsheet is the same (I presume they meant the same as normal hurricane 3).

2) NITTAKU Hurricane Neo 3 (8701) has japanese sponge. Topsheet is the same (Again, i presume the same as normal hurricane 3 neo).

3&4) Absolutely similar characteristics (as each other). Violet was produced for Japanese market.

As will shortly become clear, their information about Hurricane 3 pro is not correct. I can't yet comment on the rest though.

I have bought a sheet of nittaku hurricane 3 pro and a sheet of Nittaku hurricane 3 neo. Pro is listed on their website as available in 1.6, 1.8, and 2.0, while they only sell neo in 2.0. I ordered both in 2.0; pro in red and neo in black. They both turned out to be 2.1, according to the markings on the sponges.

The Hurricane 3 pro marking on the sponge on mine look exactly like this

While the Neo looks like this (sorry, I didn't have the foresight to take pictures before boosting, and couldn't find a good picture online)

Clearly, the hurricane 3 pro sponge is a normal DHS #20 sponge in 39 degrees, not a Japanese sponge. The +/- 2 degrees was unexpected. From what I'd read of these rubbers, they were supposed to have high quality control standards. Provincial hurricane 3 comes without any error in the hardness rating on the back of the sponge (from what I've seen of pictures online. I've never used provincial, only commercial H3 and H3 neo, both unboosted). Of course, just because it says +/2 doesn't necessarily mean that it might actually be between 37 and 41 degrees (which is a big margin for error on the DHS scale), but I'd be surprised if they went through the trouble of high quality control and then put that on the sponge. Does anyone know if commercial Hurricane 3 has error margins written on the sponge? I don't want to take my sheet off the blade and check. The Neo sponge I can't really say much about. Perhaps someone else has more information. Overall, the whole rubber on the pro is much harder than the neo. The neo is quite flexible.

One of the main things that got me interested in these rubbers was a post I read about someone (I think on this forum, I don't remember) who said they could read chinese and were reading through a chinese forum where they took apart the top sheets of a few versions of Hurricane 3, and found that Hurricane 3 national had a different pip size and structure to other versions such as commercial and provincial, and that Hurricane 3 pro was the only other version that had the same unique pips, likely meaning they were the same or similar topsheets. I don't know if Nittaku hurricane 3 neo was included in their testing. From looking at the top sheet, the pips are very clearly visible, somewhat like the sheets of Hurricane 3 national I've seen on the forums, though I've only seen pictures of black and mine is red. Once I've glued my sheets on I'll take some pictures.

Now onto the fun stuff. I decided to take my first steps into boosting by experimenting with these rubbers. I am using Falco tempo long booster. The Neo came with the usual vacuum packing and a layer of glue on the bottom. I didn't remove the layer of glue and applied the booster on top of it. The pro arrived just like any other sheet of hurricane 3, no vacuum packing, no glue. I'd read that I should add some glue first before adding the booster, so I put a thin sheet of Donic vario glue on the pro. I then put the booster over the top. I suspect I didn't wait long enough for the glue to dry, because I created rather a big mess, with bumps and lumps and unevenness. Anyway, I put a medium thick layer of the booster on both sheets and waited for around 11 hours.

This was the result:

The neo was actually a little more domed than the picture shows. I flattened it a little by hand, rather stupidly, when I took the picture.

At this point, both sponges were still quite wet, and clearly not more than half of the booster had soaked in. Since I had created a big mess on the pro, I decided to wipe everything off the sponge with my fingers and reapply. This picture was actually just after I wiped off the glue and remains of the initial booster layer, and a couple of minutes after I applied the second booster layer, slightly thinner than the previous layer, this time onto the dry sponge. I added an extra layer, very very thin, to the neo.

4 hours after that, this was the result:

Both are now more domed. Interestingly, whereas the pro had not dried after 11 hours when I put the booster over a layer of glue, now that I had wiped the glue off and put the booster straight onto the sponge, it was virtually completely dry in less than 4 hours. At this point I put a third layer of booster onto the pro, and left the neo untouched.

7 hours after the previous picture, 22 hours since initial layer was applied:

Actually the pro is domed more than this shows. If left alone it folds back on itself and a bit of the sponge rests against the topsheet. Since I didn't want to potentially get booster onto the topsheet, I aligned the two ends of the sponge so this wouldn't happen. I strongly suspect the pro 3 would have got to this point a few hours sooner if I had just put the first layer onto the sponge directly and not messed around with adding a layer of glue first. The neo is still quite wet and clearly a lot of the booster hasn't yet soaked in. Perhaps I should have removed the layer of glue it came with.

I won't be adding any more booster to the pro 3, and will wait as long as I see fit before gluing it on. I will see how the neo behaves over the coming hours and days before deciding whether to add any more booster. The neo is still much more supple than the pro, probably due to the topsheets. When they're done, they're both going on either side of a DHS pg7 (the big face means I can then put it onto my main blade, the Carbonado 145, if I really like either one). I'll then put up a review of how they play, compared to unboosted commercial Hurricane 3 neo, and hurricane 3-50 (hurricane 3 with tinarc sponge, from what I gather, so essentially hurricane 3 + softer sponge), which are both currently on the PG7.

Apologies for the long post. My aim is to get some more information about these rubbers out there. If anyone has any more information, questions, requests, or recommendations, please add them to this thread.

I'll keep this updated in the coming days with regards to how the boosting is going and how they eventually play.

Last edited: