Argh! Not this crap again. COR, speed after impact(my bad, velocity after collision, I insist), ratio of tangential COR to normal COR(throw angle, FFS), paddles don't generate energy unless you burn 'em and on and on. *bleep* me. This is disappointing. Hard-headed engineer has shown little if any growth in 10 friggin' years...

Here's the deal. "

COR is an index that describes the relative elasticity of an impact." It's a mathematical description of "given this initial condition and this final condition, this is

what happens". It doesn't explain

why it happens this way or

what causes it to happen this way.

Hard-headed engineer could work out the CORs from the real-world data that yours truly quoted above and argue until he's blue in the face and it still won't answer the OP's question.

To answer that one has to look further, in this case

elasticity of the material, or elastic modulus.

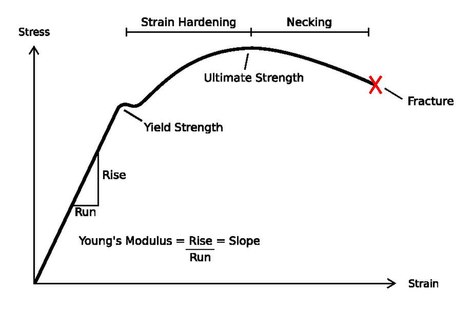

To keep things simple, the stress-strain curve of a vulcanized rubber would look something like the figure below. Stress and strain here mean the force taken to displace(stretch/compress) the material. The elastic modulus, AKA Young's modulus in this case, is the linear region of the plot.

The steeper the slope, the higher the stress required for the respective strain, and the higher the Young's modulus. In the real world, rubber acts viscoelastically, so the storage modulus, loss modulus and tan delta(a measure of hysteresis that leads to damping) come into play as well.

Remind yourself that

vulcanization adds elasticity to rubber because crosslinks are formed during the process and the higher the crosslink density the harder it gets, until a certain point. This is why harder rubber takes more force to stretch and if the force is not enough to reach the sponge, much of the energy is lost in the topsheet, according to data from Butterfly. Think of the force required to draw a heavy bow vs a light bow.

Now, what hard-headed engineer doesn't realize is that oddball anti rubber behaves beyond the elastic region, into the plastic region(permanent deformation). What high performance rubber would do that? Who'd be dumb enough to make that comparison?

Note the "craters" all over the topsheet that don't "recover".